TABLE OF CONTENT

- INTRODUCTION

- CRYO—-

- TYPES OF CRYOGENIC TREATMENTS

- ABSOLUTE ZERO

- PRODUCTION OF LOW TEMP

- METHODS OF LIQUIFICATION OF AIR

- APPLICATIONS

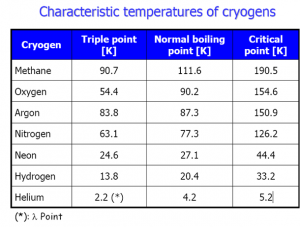

- CRYOGENS

- CONCLUSION

- CRYOGENIC LABORATORY

INTRODUCTION

- Cryogenics – the study and use of materials at extremely low temperatures

- Inputs from three major disciplines, namely PHYSICS , MECHANICAL ENGINEERING, CHEMICAL ENGINEERING

- Such low temperatures cause changes in the physical properties of materials that allow them to be used in unusual engineering, industrial, and medical applications

- For example, in the cryogenic temperature range, air becomes a liquid—or even a solid—and living tissue freezes instantly

- Cryobiology: Branch of biology involving the study of the effects of low temperatures on organisms

- Cryosurgery: Branch of surgery applying very low temperatures (down to -196 °C) to destroy malignant tissue, e.g. cancer cells.

- Cryonics: The emerging medical technology of cryopreserving humans and animals with the intention of future revival.

- Cryoelectronics: Field of research regarding superconductivity at low temperatures.

- Cryotronics: Practical application of cryoelectronics.

TYPES OF CRYOGENIC TREATMENT

- SHALLOW CRYOGENICS, the objects are cooled down to temperature of approximately -85oC

- FLOODING, first the object is taken to -85oC, then the chamber is flooded with liquid nitrogen to reduce the temperature furthur

- DEEP CRYOGENICS TREATMENT, Subjects the objects to the temperature of approximately -185oC

ABSOLUTE ZERO

- Absolute zero is a temperature marked by a 0 entropy configuration. It is the coldest temperature theoretically possible and cannot be reached by artificial or natural means

PRODUCTION OF LOW TEMPERATURE

- HEAT CONDUCTION: When bodies are in contact, heat flows from the body with the higher temperature to the body with a lower temperature. Can occur between any and all forms of matter. It is essential in the production of cryogenic temperatures and environments.

- EVAPORATIVE COOLING: Humans lose heat by this mechanism. Atoms and molecules in the gaseous state are moving faster than the atoms and molecules in the liquid state. Adding heat energy to the particles in a liquid makes them gaseous

- THE JOULE-THOMSON EFFECT: Allowing a gas to expand very rapidly causes its temperature to drop dramatically. Reducing the pressure on a gas accomplishes the same effect.

- Ordinary house hold refrigerators and air conditioners operate on this principle.

METHODS OF LIQUIFICATION OF AIR

- Linde’s System also known as Hampson System

- Claude’s System

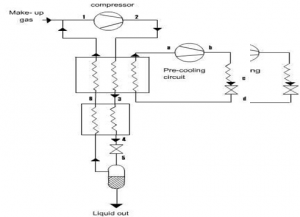

LINDE’S SYSTEM

- Clean dry air is taken from the atmosphere and is compressed up to 200 bar

- The high pressure enters into counter flow air to air heat exchanger and is then throttled to atm – pressure

- The J-T cooling up to expansion causes a lowering of temperature and this cool air is passed through heat exchanger where it cools the incoming high section

- Thus the temperature at the valve is progressively lowered until the liquefaction temperature is reached

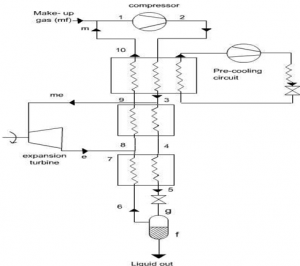

CLAUDE’S SYSTEM DIAGRAM

- Claude’s System yields more efficient cycle than Linde’s System

- The expansion through an expansion valve is an irreversible process.

- In Claude’s System energy is removed from the gas stream by using an expansion engine or expander.

- The expansion process is isentropic and much lower temp is attained then isenthalpic expansion

- In Claude’s System the gas is first compressed to pressure of the order 4 Mpa.

How Claude’s System is more efficient than Linde’s System

- The advantage of the Claude’s System is, it operates at low compression ratio compared with Linde’s process.

- Secondly the temperature of air before coming to the expansion valve in Claude system is lower than the Linde system.

Cryogenic Devices

APPLICATION OF CRYOGENICS

- Aerospace-cryogenic engines

- Medical Field

- Manufacturing field

- Electronics Field

- Fuels research

- Miscellaneous uses

CRYOGENIC ENGINES IN AEROSPACE

- First operational Cryogenic Rocket Engine is 1961 NASA designed RL-10 LOX LH2 rocket engine

- The second-stage Pratt & Whitney RL10B-2 engine is based on the 30-year heritage of the reliable RL10 engine

- At Mahendragiri in Tamil Nadu, is the LPSC. The system involves materials working at 23K and pumps at speeds of 40,000 rpm. Complex metering, monitoring, integrating technologies involved. The engines required to fire for 700 seconds during the final stage of a launch providing 7 tones of thrust

- Engine works on ‘Staged Combustion Cycle’ with an integrated turbo pump running at 42,000rpm. Also equipped with two steering engines developing a thrust of 2 kN each to enable three-axis control of the launch vehicle during the mission

- Closed loop control of both thrust and mixture ratio, which ensures optimum propellant utilization for the mission

- To know how cyrogenics plays vital role in space shuttle.. watch this video :

https://www.youtube.com/watch?v=LjG-4oR7JxI

CRYOSURGERY

- Cryosurgery- Use of extreme cold produced by liquid nitrogen (or argon gas) to destroy abnormal tissue.

- Used to treat external tumors, such as those on the skin.

- For internal tumors, liquid nitrogen is circulated through a hollow instrument called a Cryoprobe.

- Used since many years in the treatment of skin cancer

CRYOGENICS IN MANUFACTURING FIELD

- Cryogenic treatment works on Reamers, Tool bits, Tool punches, Carbide Drills, Carbide Cutters, Milling Cutters, Files, Knives, Reciprocating Blades, Dies and cutting tools

- Stress relieved ferrous and non ferrous castings and forgings for enhanced dimensional stability and surface finish

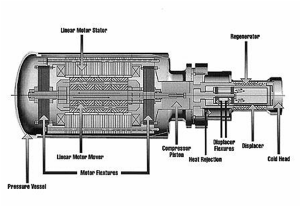

CRYOGENICS IN ELECTRONICS FIELD

- Super conducting electronic devices like SQUID (Super conducting quantum interference device) are used in sensitive digital magnetometers and voltmeters

- Zero friction bearings use magnetic field instead of oil or air, derived from the Meissner Effect associated with super conductivity.

- Super conducting electric motors are constructed approaching zero electric loses

Nuclear Magnetic Resonance Spectroscopy (NMR)

Most common method to determine the physical and chemical properties of atoms by detecting the radio frequency absorbed and subsequent relaxation of nuclei in a magnetic field. Strong magnetic fields are generated by supercooling electromagnets. Liquid helium(BP 4K) is used to cool the inner coils. Cheap metallic superconductors can be used for the coil wiring. So-called high-temperature superconducting compounds can be made to superconduct with the use of liquid nitrogen(BP 77K)

Magnetic Resonance Imaging (MRI) :

Complex application of NMR where geometry of the resonances is deconvoluted and used to image objects by detecting the relaxation of protons that have been perturbed by a radio-frequency pulse in the strong magnetic field. Mostly used in health applications

Electric Power Transmission:

- Superconductors could be used to increase power throughput. Require cryogenic liquids such as nitrogen or helium to cool special alloy-containing cables to increase power transmission. Field is the subject of an agreement within the International Energy Agency.

Frozen Food:

- Transportation of large masses of frozen food. Food is freezed in war zones, earthquake hit regions, etc. Cryogenic food freezing is also helpful for large scale food processing industries

Forward looking infrared (FLIR)

Many infra-red cameras require their detectors to be cryogenically cooled

Blood banking

Certain rare blood groups are stored at low temperatures, such as −165 °C

Special effects

Liquid nitrogen and CO2 has been built into nightclub effect systems by Kryogenifex to create a chilling effect and white fog that can be illuminated with colored lights.

- Inert Gases: Do not react chemically to any great extent. Do not burn or support combustion. Includes Nitrogen, Helium, Neon, Argon and Krypton

- Flammable Gases: Some cryogenic liquids produce a gas that can burn in air. Includes Hydrogen, Methane and Liquefied Natural Gas

- Oxygen: Many non-combustible materials can burn in the presence of Liquid Oxygen. Organic materials react explosively with Liquid Oxygen. Hazards and handling precautions of liquid oxygen is considered separately from other cryogenic liquids

FACILITIES AT OUR CRYOGENICS LABORATORY

- Oil Diffusion Vacuum Pumping System with Measuring Guages, Trolley Heater & Oil

- Dewar vessels ( Model T-26-A 0110 capacity – 25 Lt. ) ( Model T-55-A 0110 capacity – 50 Lt. )

- VPF 100 Liquid Nitrogen variable temperature Dewar with Controller & Trolley

- Servotronic Digital (6 digit) Temperature Indicator ( PT-100 -200C to 100C six channel 230 VAC )

- Piezo-Electric Transducer with Accessories

- Data Logger with Software for online display ( ModelNo: MICROLOG 6102 + CST 27)

- Helium Compressor

Projects on Cryogenics

- QUASI-ISOTHERMAL EXPANSION ENGINE FOR CRYOGENIC AUTOMOTIVE PROPULSION

- CRYOGENIC ENGINE IN ROCKET PROPULSION

- DEEP SPACE COOLING TO ELIMINATE CRYOGENIC VENTING

- APPLICATION OF CRYOTREATMENT FOR ENHANCEMENT IN TOOL LIFE